3D PRINTING EXPLAINED

From digital designs to physical reality within hours with 3D printing. Heres how it works...

PROVIDE A 3D DIGITAL DESIGN

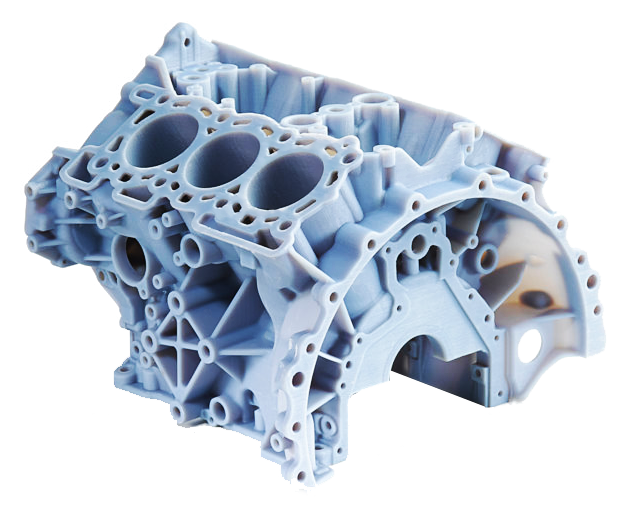

3D printing transforms 3D model data files into actual physical reality; we have been 3D printing models of Trains, Planes, Automobiles, Rockets, Speed boats and Houses all from the push of a computer button and a lot of investment in the latest technology.

WE UPLOAD TO OUR 3D PRINTERS

Every 3D printer has a computer attached to it with the 3D printer manufactures software controlling it. The data is loading into control software, which tells us the material usage, the overall print time and the time the 3D print will finish.

Then We click the “start 3d Print” button and wait for it to finish, unlike 2D printing the print normally runs overnight for several hours to complete a part.

ADDITIVE LAYER MANUFACTURING

The data is loaded into the driver software:-the 3D printer software cuts the data into layers, each layer is printed just like a 2D printer in specified layer thickness , then when the layer is finished, the print bed is lowered buy the same layer thickness, so the next layer can be printed on top.

PHYSICAL OBJECT 3D MODEL DELIVERED TO YOU

Once the 3D print has been completed, it is removed from the machine and the support material is physically cleaned off. The 3D model is the packed carefully, slipped to a box, Fedex collect every day, usually with a next day delivery to you. It’s a simple as that.

Get your model 3d printed now

Print Now